Complete Guide to Earthing: Types, Installation, and Best Practices for Electrical Safety

Summary

Earthing is a critical component of any electrical system, ensuring safety for both people and equipment. From protecting against electrical shocks to maintaining the longevity of electrical devices, a properly designed earthing system is indispensable. This guide covers types of earthing, installation processes, factors to consider, advantages and disadvantages, and maintenance practices. By understanding these principles, electrical engineers, electricians, and industry professionals can ensure reliable and safe electrical installations.

📘 Table of Contents (Click to Expand/Hide)

1. Introduction: The Importance of Earthing

Earthing, also referred to as grounding, is one of the fundamental aspects of electrical safety. It ensures that excess electrical current, typically due to a fault or lightning strike, is safely conducted into the earth, preventing damage to equipment and reducing the risk of injury or death.

Electrical systems are inherently dangerous without proper earthing. Even a minor fault in wiring can result in electric shocks or fire hazards. Modern electrical systems, from residential buildings to industrial plants, rely heavily on a robust earthing system to maintain operational safety.

Beyond safety, earthing contributes to equipment longevity and system stability. It prevents voltage fluctuations, limits overvoltage conditions, and protects sensitive electrical devices from damage. Regulatory bodies across the globe mandate proper earthing as part of electrical safety codes. In India, standards such as IS 3043:2018 provide guidelines on designing and implementing effective earthing systems.

Proper earthing also supports efficient operation of surge protection devices (SPDs) and residual current devices (RCDs), which are essential in industrial and commercial setups. Without a well-designed earthing system, these safety mechanisms cannot function optimally.

2. What Is Earthing?

Earthing is the process of connecting electrical installations to the ground through a conductive path, allowing fault currents to flow safely into the earth. The primary goal is to reduce the risk of electric shock and protect electrical equipment from damage due to faults.

There are two main types of earthing in technical terms:

- System Earthing (Neutral Earthing): Involves connecting the neutral point of transformers or generators to the ground to stabilize voltage levels.

- Equipment Earthing (Protective Earthing): Involves connecting metallic parts of equipment to the earth to prevent electric shock in case of insulation failure.

The concept of earthing is based on the principle that the earth acts as an infinite reservoir capable of absorbing excess electrical charges. By providing a low-resistance path to the ground, earthing ensures that any fault current dissipates quickly, maintaining system safety and operational integrity.

3. Why Is Earthing Necessary?

Earthing is essential for several critical reasons:

- Safety of People: By providing a low-resistance path for fault currents, earthing reduces the risk of electric shock or fatal accidents.

- Protection of Equipment: Electrical surges, lightning strikes, and insulation failures can damage sensitive devices. Proper grounding mitigates these risks.

- System Stability: Earthing stabilizes voltage during normal operation, preventing fluctuations that can disrupt equipment performance.

- Regulatory Compliance: National and international electrical codes mandate proper earthing as a safety requirement.

- Fire Prevention: Fault currents can cause overheating of wires or insulation. Earthing safely channels these currents to the ground, reducing fire hazards.

Industries, commercial setups, and residential complexes rely on earthing to ensure continuous, safe, and reliable power supply. Without proper grounding, even minor faults can escalate into costly damage or serious injuries.

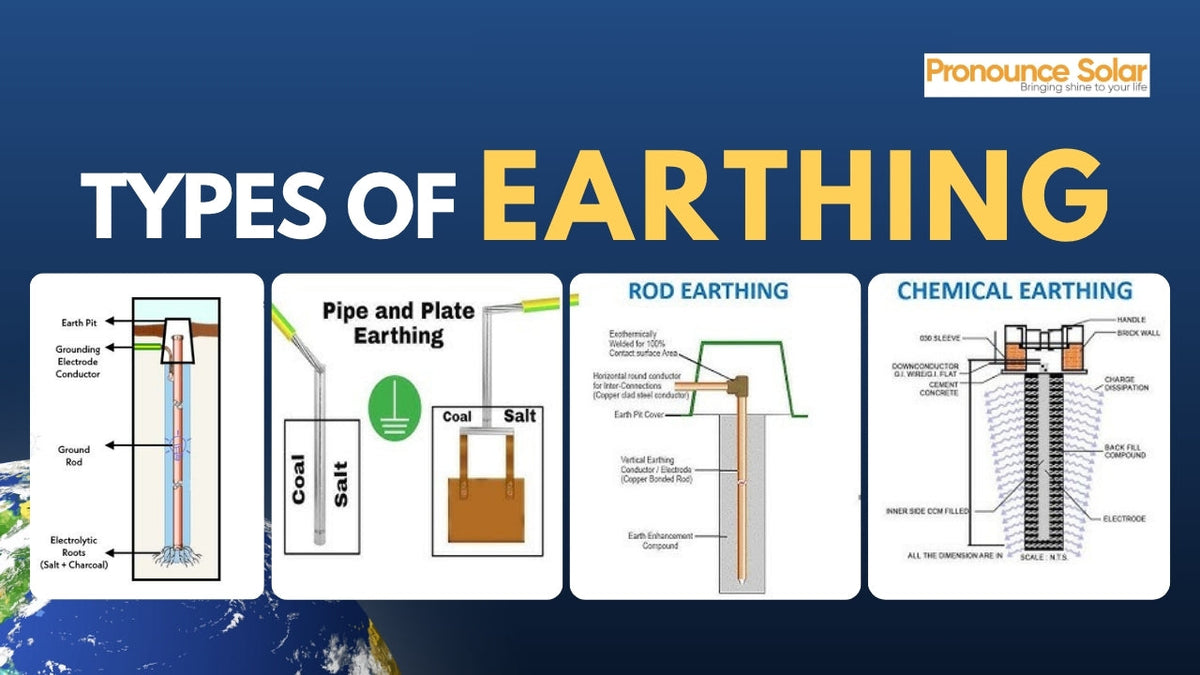

4. Types of Earthing

There are multiple types of earthing systems, each suited for specific applications based on soil conditions, space availability, and electrical load requirements.

4.1 Plate Earthing

Plate earthing involves burying a metallic plate (usually copper or galvanized iron) vertically in the ground and connecting it to the electrical system through a conductor.

- Commonly used in residential and small commercial installations.

- Offers low resistance due to large surface area.

- Requires periodic inspection to prevent corrosion.

Plate earthing is ideal for locations with moderate soil resistivity and sufficient space.

4.2 Pipe Earthing

Pipe earthing uses a hollow galvanized iron or copper pipe filled with conductive materials like salt or charcoal to improve conductivity.

- Suitable for industrial installations requiring higher fault current handling.

- Conductive fillings ensure low resistance, even in dry soil conditions.

- Installation is relatively simple, and the system is easy to maintain.

Pipe earthing is widely recommended for areas with variable soil moisture content.

4.3 Rod Earthing

Rod earthing involves driving metal rods (copper or galvanized steel) into the ground.

- Rods are usually 3–5 meters in length.

- Common for small-scale and residential electrical systems.

- Requires minimal space and can be installed in compact areas.

- Rod corrosion and soil resistivity are key factors for maintenance.

Rod earthing is preferred for locations with shallow soil depth but moderate moisture content.

4.4 Strip Earthing

Strip earthing uses a metallic strip buried horizontally underground, typically made of copper or galvanized iron.

- Provides low-resistance path for fault currents due to large surface contact with soil.

- Ideal for industrial or large commercial plants.

- Horizontal layout requires adequate space for effective grounding.

Strip earthing is effective in areas with high soil resistivity or where multiple equipment needs to be grounded in the same system.

4.5 Earthing through Water Pipe

This method connects the electrical system to metallic water pipelines, providing a conductive path to the ground.

- Works well in urban areas with accessible water pipelines.

- Must ensure that the pipeline is metallic and in direct contact with the earth.

- Provides moderate grounding for small commercial and residential systems.

Care must be taken to prevent corrosion or damage to water supply pipelines due to continuous electrical current flow.

4.6 Earthing with Earth Electrode

This involves using a dedicated earth electrode, typically made of copper or galvanized steel, connected to the electrical system through conductors.

- Ensures low-resistance path for fault current.

- Can be installed vertically or horizontally, depending on soil conditions.

- Requires periodic inspection and testing to ensure system reliability.

Earth electrodes are widely used in industrial setups where high fault currents are expected.

4.7 Chemical Earthing

Chemical earthing involves embedding electrodes in a special chemical compound to maintain low resistance.

- Suitable for rocky or high-resistivity soil areas.

- Provides stable and long-lasting grounding.

- Reduces maintenance compared to traditional methods.

Chemical earthing is becoming popular in industrial and high-voltage applications due to consistent performance and minimal soil dependency.

5. Factors to Consider When Choosing Different Types of Earthing Systems

Choosing the right earthing system depends on multiple technical and environmental factors:

5.1 Soil Resistivity

Soil resistivity significantly impacts the effectiveness of earthing. Low-resistivity soils (moist clay) conduct electricity better than sandy or rocky soils. Soil resistivity tests are performed before selecting the earthing type.

5.2 Space Availability

Space constraints can determine whether vertical rods, horizontal strips, or plate earthing is feasible. Compact sites may require rod or pipe earthing, while large industrial areas can accommodate horizontal strip or plate earthing.

5.3 Moisture Content

Moist soil improves conductivity, reducing earth resistance. Dry soils require additional measures, such as chemical compounds or water pipe earthing, to maintain low resistance.

5.4 Corrosion Resistance

Corrosion of electrodes or pipes can increase resistance over time. Material selection (copper vs. galvanized steel) and protective coatings are crucial to ensure long-term reliability and minimal maintenance.

6. The Process of Earthing Installation

A professional earthing installation involves systematic evaluation, selection, installation, and testing:

6.1 Site Evaluation

- Assess soil type, resistivity, moisture content, and space.

- Determine load requirements and fault current capacity.

6.2 Selection of Earthing System

- Choose plate, rod, pipe, strip, or chemical earthing based on site evaluation.

- Consider long-term maintenance and cost.

6.3 Installation and Wiring

- Excavate the site and install electrodes with proper conductive materials.

- Connect the earthing system to the electrical panel and equipment using adequate gauge conductors.

- Ensure all connections are tight and corrosion-protected.

6.4 Testing and Maintenance

- Conduct earth resistance testing using a digital tester or Megger.

- Maintain logs of readings to detect deviations over time.

- Periodic inspection of electrodes, soil moisture, and corrosion prevention measures is essential.

7. Advantages and Disadvantages of Different Types of Earthing

|

Type |

Advantages |

Disadvantages |

|

Plate |

Low resistance, effective |

Requires space, corrosion risk |

|

Pipe |

Easy installation, durable |

Needs conductive filling, periodic maintenance |

|

Rod |

Compact, simple |

Limited depth, affected by dry soil |

|

Strip |

Low resistance, good for multiple equipment |

Requires more space, complex installation |

|

Water Pipe |

Accessible in urban areas, moderate cost |

Risk of corrosion, limited to metallic pipelines |

|

Earth Electrode |

Reliable, low resistance |

Costlier, periodic testing required |

|

Chemical |

Stable performance, minimal soil dependency |

Higher initial cost, chemical handling required |

8. Conclusion

Earthing is an indispensable aspect of electrical safety. Selecting the appropriate type depends on soil conditions, moisture content, space availability, and expected fault currents. Proper installation, periodic testing, and maintenance ensure long-term reliability and protection for both people and equipment. Implementing a robust earthing system is not just a regulatory requirement but a critical step in preventing electrical hazards in residential, commercial, and industrial setups.

Readers Comment

Earthing is really important. My solar vendor was avoiding solar earthing. Thank for the blog.

very informative

Leave a comment We will reply you back through Email.